MACE 61058: Plasticity – Lab

Lecturers: Dr. Henry Tan

Objective

- Using uniaxial tensile test to compare the true strain – stress curves of three specimens: steel, aluminum and copper.

- Using Bi-axial tension test (bulge test) to compare the equivalent yield stress versus equivalent plastic strain curves of two materials (aluminum and brass).

- Compare the equivalent yield stress versus equivalent plastic strain curves for aluminum and brass from the uniaxial tensile test and the bulge test, respectively.

Schedule

Time: Monday (23/3)

Tensile test

10.00am start at the Instron (Pariser Building, A floor). You can go from the elevator to A floor, then turn right (a few steps) and right, enter the door of the lab.

Load versus extension graph to be plotted during test, and the data to be available for students to do further analysis. Since Instron is an advanced machine requiring the skills of a trained operator, Mr David Mortimer will operate the machine.

Bulge test

10.30am (ish)

The students will move through to P/A37 where Mr Peter Hassall will demonstrate the bulge test.

Uniaxial tensile specimen

The specimens are 12.5mm in diameter. The gauge length for

the test specimen is ![]() .

.

Three specimens will be tested (steel, aluminum and copper) in a straight tensile test to failure.

Tensile test machine

Figure 1. Schematic representation of INSTRON tension test machine

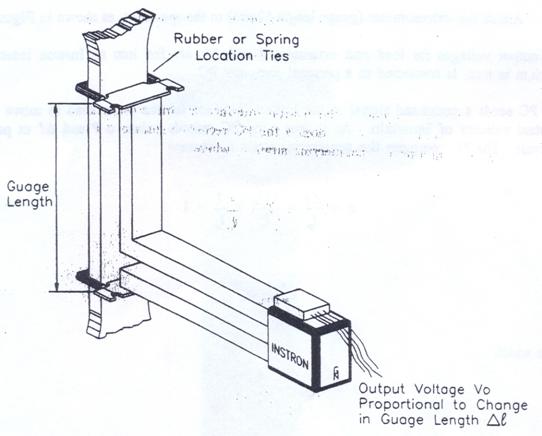

Strain gauge Extensometer

Figure 2. Schematic representation of strain gauge extensometer fixed to tensile specimen